Sewer Line Repair in Portland, OR

Professional Emergency Sewer Repair Services in Portland

As a sewer repair business, we utilize a variety of sewer repair methods to fix sewers and drains. Pipe lining, (also known as Cured-in-place pipe or CIPP), pipe bursting, directional drilling, and excavation are some of the techniques we employ. At Sewer Renewal Specialists, we recognize the importance of a functional sewer line in maintaining the integrity of your home's plumbing system. Our dedicated team of professionals is committed to providing tailored solutions to address sewer line problems, ensuring the longevity and optimal performance of your sewer infrastructure.

For experienced sewer line repair in Portland, give our team a call at (971) 803-5240 or request an estimate today!

Common Causes of Sewer Line Issues

Understanding the common causes of sewer line problems is crucial for homeowners in Portland. Factors such as tree root intrusion, aging pipes, ground shifting, and debris accumulation can lead to cracks, leaks, and blockages in sewer lines. Our comprehensive diagnostic approach allows us to identify the root cause of the issue, enabling us to implement precise and effective repair solutions.

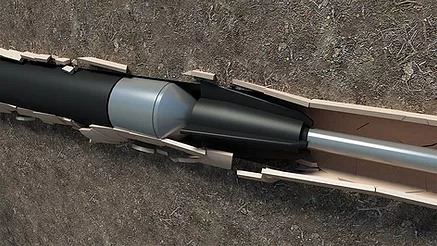

Pipe Bursting

When sewage backs up into your home, you need a fast solution that will restore flows through your sewer as quickly as possible. This process uses a bursting tool inserted into one end of the host sewer pipe using an insertion pit.

A winch is attached to the head of the tool and placed at the opposite end of the pipe. The winch line guides the bursting tool through the old pipeline.

The tool is pulled back through the sewer pipe applying a strong rotating force, which breaks up and shatters the old sewer line as it passes through. The machine then pushes those pieces out of the way as it replaces the sewer pipe with a new one. The process is done from outside of your home and can be completed in under an hour.

The Benefits of Pipe Bursting

With pipe bursting, only two access points are needed for repairs, meaning fewer disruptions for homeowners in terms of property damage caused by additional trenches being dug.

Furthermore, the strength of the newly installed pipe is often better than the old one, providing long-term benefits. Pipe bursting can also be completed in less time than other repair methods and at a similar cost.

Why Choose Sewer Renewal Specialists?

-

CIPP/Pipe Lining Specialists

-

Affordable Pricing

-

24/7 Emergency Services

-

Financing Offered

-

Free Estimates

-

45-Year Warranty

Directional Drilling

Another sewer replacement option is augering or horizontal directional drilling (HDD). This method works to cut through rocks and underground structures much like how oil drillers “drill” oil wells thousands of feet below the ground.

An auger is inserted into the sewer pipe and a cutting head is attached to its end. The space created between the sewer line and the cutting head allows for debris such as rocks and sediment to be pushed out of the way while slowly crisscrossing through the sewer system to make way for a new sewer pipe.

What Are the Benefits of Directional Drilling?

Directional drilling is another minimally disruptive and quick sewer repair method. It also allows for maneuverability in hard-to-reach areas with tight curves and fractures which are difficult to navigate with traditional excavation methods.

Can Sewer Line Repair Disrupt My Portland Property?

Concerns about property disruption during sewer line repair are understandable. At Sewer Renewal Specialists, we prioritize minimizing the impact on your property. Our trenchless sewer line repair techniques allow us to address issues without extensive excavation. Whether it's pipe relining or pipe bursting, these methods significantly reduce disruption, preserve landscaping, and expedite the repair process. We ensure that your Portland property is treated with the utmost care during every step of the repair process.

State-of-the-Art Technology for Precision Repair

Sewer Renewal Specialists employs cutting-edge technology to ensure precise and efficient sewer line repairs in Portland. Our trenchless repair methods, including pipe lining and pipe bursting, minimize the need for disruptive excavation while providing long-lasting solutions to address cracks, leaks, and other sewer line issues.

The Sewer Renewal Specialists Commitment

Choosing Sewer Renewal Specialists means choosing a team dedicated to excellence, integrity, and customer satisfaction. Our transparent communication, fair pricing, and commitment to quality make us the preferred choice for sewer line repair in Portland.

Contact Sewer Renewal Specialists Today

If you're experiencing signs of a damaged sewer line or are in need of professional sewer line repair in Portland, don't hesitate to contact Sewer Renewal Specialists. Trust us to restore the functionality of your sewer system with precision and care.

We are faster, cheaper, and less invasive than other companies still stuck digging trenches. Give us a call at (971) 803-5240 or contact us online today!

-

"Prompt, professional, and fair."Sewer Renewal Specialists replaced our Orangeburg sewer pipe promptly and professionally. They kept us updated throughout the process and fixed the sidewalks. Their price was fair. Recommended!Amy T.

-

"Beyond professional, very generous."We had sewer drainage issues after getting a new roof. Sewer Renewal Specialists fixed it in 20 minutes at no charge! It was beyond professional and very generous. Thank you so much. Guess who we’ll call for our next sewer situation?Annette C.

-

"Excellent communication and quick repairs."We had a sewer backup and contacted a competitor who quoted an astronomical price. Our friends recommended Sewer Renewal Specialists, and they were excellent from first contact. Great advice, prompt communication, and quick repairs. Highly recommend Sewer Renewal Specialists.Seth H.